Proximity sensors detect presence or absence of objects without physical contact. Inductive and capacitive proximity sensors are two common types used for different applications.

A proximity sensor is an electronic solid-state device used to indicate the presence of an object without making physical contact. The proximity sensor is a very useful device in hazardous areas such as oil refineries and not so hazardous areas such as car door detection systems. Proximity sensors do not use any type of physical moving parts instead they allow signals to transmit through them when something that is being monitored comes in close proximity of the sensing area. Despite the process, they are still referred to as proximity switches.

Where are Proximity Sensors Used?

Proximity sensors are to be used when the object that needs to be detected is too small, lightweight or too soft to operate a mechanical switch. When there is a need for rapid response and high switching rates such as the counting objects, proximity sensors are ideal for the task. Proximity sensors should also be used when there’s a need to sense material through nonmetallic barriers such as glass, bottles, plastic, or paper cartons or when working in hostile environments that demand electrical isolation from the product being monitored. Proximity sensors are also needed when there is a need to have a device that provides long life and reliable service or when there are vast electronic control systems that need to be free of chattering contacts to produce an accurate analysis of what’s being monitored.

Proximity Sensor Types

There are two main types of proximity sensors, that achieve these need, these include the inductive and capacitive proximity sensors.

How does an Inductive Proximity Sensor work?

The inductive proximity sensor as seen in Figure 1 (a) is used to detect both ferrous metals that contain iron and can be magnetized and nonferrous metals such as what we use to conduct electricity and copper. Inductive proximity sensors operate under the electrical principle of magnetism when a fluctuating current induces the voltage in a target object.

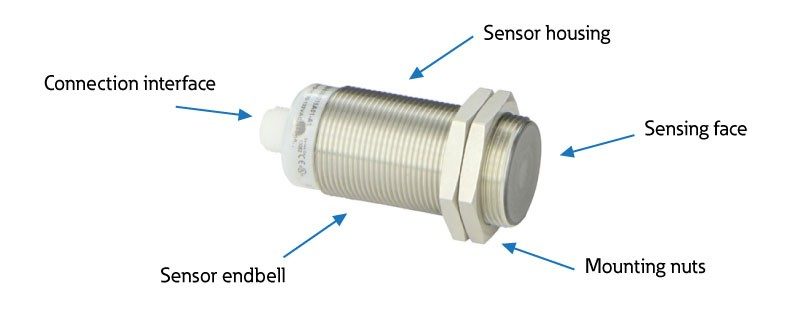

Fig. 1 (a): Inductive Proximity Switch

The inductive proximity sensor contains a certain type of solid-state control system. It contains an oscillator circuit that generates a high-frequency magnetic field. When the metal object enters the field, it disturbs the magnetic field, this disturbance results in a change of state in the high-frequency circuit.

Fig. 1 (b): Inductive Proximity Switch Circuit Diagram

Inductive proximity sensors are intended to be wired into motor control circuits or electronic control circuits with a voltage rating of 24 V DC. Most proximity sensors come in two basic configurations one is 3 wire configuration while the other one is a 2 wire configuration. The three wire proximity sensor is required to be powered up at all times so the sensor must have two wires connected to a constant voltage source to operate the electronic circuitry of the device. The third wire of the proximity inductive switch is the contact wire which can come normally open or normally closed. Some proximity switches can contain both so the total number of wires coming from the unit can total to be 4.

The two wire proximity sensor is intended to be connected in series with the load is to control. In its natural state, there’s enough current that must flow through the circuit to keep the sensor active. This current is referred to as the leakage current and typically may range from 1 to 2 mA.

How to select an Inductive Proximity Sensor?

An inductive proximity sensor typically consists of the following components:

| Coil | The coil is the key sensing component that produces an electromagnetic field. |

| Ferrite core | The ferrite core concentrates and enhances the magnetic field generated by the coil. |

| Oscillator circuit | The oscillator circuit produces an alternating current (AC) signal to energize the coil. |

| Detection circuit | The detection circuit measures changes in the inductance of coil caused by the presence of a metallic object. |

| Output circuit | The output circuit gives the signal output, which can be either analog or digital, indicating the absence or presence of the detected object. |

| Housing | The housing encloses and protects the sensor’s internal components. |

| Connection terminals | The connection terminals provide the electrical interface for signal output and power supply connections. |

These components work together to detect the presence of metallic objects in proximity to the sensor.

Inductive Proximity Sensor Components

When selecting an inductive proximity sensor, consider the following factors:

| Sensing range | Pick a sensor with a range appropriate for your application requirements. |

| Operating voltage | Make sure that the sensor functions within the voltage range of your system. |

| Output type | Determine whether you need an analog or digital output, depending on your application requirements. |

| Material compatibility | Validate that the sensor is able to detect the particular object you intend to sense. |

| Environmental considerations | Consider factors such as humidity, temperature, and any likely interference in the application environment. |

| Accuracy and reliability | Assess the specifications of the sensor for reliability and accuracy to confirm it meets your anticipated performance level. |

| Mounting options | Consider the available mounting options to make sure appropriate installation in your application. |

By considering these factors, you can make an informed decision when selecting an inductive proximity sensor.

Figure 2. Inductive Proximity Sensor Components

How does a Capacity Proximity Sensor work?

The capacitive proximity sensor is similar to the inductive proximity sensor, as shown in figure 1 (b). The main difference between the two, capacitive proximity sensor produces an electrostatic field instead of a magnetic field and the sensing area of the capacitive proximity sensor can be actuated by both conductive and non-conductive materials. A capacitive proximity sensor contains a high-frequency oscillating circuit along with a sensing surface formatted by two metal plates. When an object or some type of material gets in the sensing range it disturbs the electrostatic field of the metal plates, changing the capacitance of the proximity sensor, this change results in a change of state in the operation of the proximity sensor.

How to select a Capacitive Proximity Sensor?

When choosing a capacitive proximity sensor, take into account the following factors:

| Sensing Range | Establish the required sensing range based on the distance between the target object and the sensor. |

| Target Material | Various capacitive sensors are intended to sense particular types of materials (solid, liquid, or powder). Consider the material properties of the target object. |

| Environment | Assess the environmental conditions, for instance temperature, presence of liquids or dust, and humidity, to make certain the sensor is appropriate for the proposed application. |

| Mounting Options | Check the mounting options, for example flush or non-flush mounting, and opt the one that best suits your application needs. |

| Output Type | Choose the preferred output type, whether digital (on/off signal) or analog (continuous current or voltage), depending on the application needs. |

| Power Supply | Verify the required voltage and current requirements for the sensor’s power supply. |

| Electrical Compatibility | Make sure the electrical characteristics or the sensor, like signal compatibility and voltage levels, match the control system or interface’s requirements. |

| Special Features | Take into account any further features that may be useful, like flexible sensitivity, built-in temperature compensation, or background suppression. |

By considering these factors, you can select a capacitive proximity sensor that is suitable for your specific application.

Capacitive Proximity Sensor Components

The components of a capacitive proximity sensor typically include:

| Sensor Head | This is the key sensing component that detects variations in capacitance when an object gets in the sensing range. |

| Dielectric Material | The dielectric material establishes a protective layer on the sensor head and assists in establishing the capacitance change when an object approaches. |

| Oscillator Circuit | The oscillator circuit produces an oscillating electrical signal, affected by the change in capacitance. It functions as a reference to detect the presence or absence of an object. |

| Detection Circuit | The detection circuit processes the signal coming from the oscillator circuit and transfers it into a usable output, like a voltage or current, indicating the absence or presence of the target object. |

| Signal Conditioning Circuit | In certain circumstances, capacitive proximity sensors may incorporate signal conditioning circuitry to modify the response time, sensitivity, or filtering of the output signal. |

| Housing and Connectors | The sensor modules are enclosed within a protective frame, which may be made of several materials depending on the application needs. Connectors are supplied for easy integration with control systems or interfaces. |

These components work mutually to detect variations in capacitance and provide a dependable proximity sensing solution in diverse industrial applications.

Figure 3. Capacitive Proximity Sensor Components

Key Takeaways on Proximity Sensors

Proximity sensors are devices that detect the presence or absence of an object within their sensing range without physical contact. They operate based on different principles such as inductive proximity sensors, which detect metallic objects, and capacitive proximity sensors, which sense changes in capacitance to detect both conductive and non-conductive materials.

Frequently Asked Questions (FAQs) about Proximity Sensors

What is a proximity sensor?

A proximity sensor is a device that detects the presence or absence of an object without physical contact.

How does an inductive proximity sensor work?

An inductive proximity sensor generates an electromagnetic field and detects changes in the field when a metallic object is within its range, triggering a response.

How does a capacitive proximity sensor work?

A capacitive proximity sensor uses changes in the capacitance of its sensing area to detect the presence of objects, including non-metallic materials.

What are the typical applications of inductive proximity sensors?

Inductive proximity sensors are commonly used in industrial automation, robotics, and assembly lines to detect metal objects, monitor position, or control processes.

What are the typical applications of capacitive proximity sensors?

Capacitive proximity sensors find applications in industries such as food processing, packaging, and material handling, where they can detect objects regardless of their material composition.

What are the key factors to consider when selecting a proximity sensor?

Important considerations include the sensing range, environmental conditions (e.g., temperature, humidity), target material, response time, and electrical compatibility with the system.

Can proximity sensors be used in harsh environments?

Yes, some proximity sensors are specifically designed to withstand harsh conditions such as high temperatures, moisture, and vibration, making them suitable for challenging industrial environments.

Can proximity sensors be used for both presence detection and distance measurement?

While proximity sensors primarily detect the presence or absence of objects, certain types such as time-of-flight sensors or laser-based sensors can provide distance measurement capabilities.